Metal Casting core ideas shared in a smooth explanation

Wiki Article

The Relevance of Steel Foundries: A Comprehensive Review of Their Effect On Production

Steel factories are integral to the production landscape. They change basic materials into components that offer varied industries, from vehicle to aerospace. Their competence in alloy solution and spreading techniques guarantees the production of resilient parts. The market faces obstacles that can improve its future. Understanding these dynamics reveals real relevance of foundries in technological and economic contexts. What lies ahead for this critical sector?The Duty of Metal Factories in the Manufacturing Refine

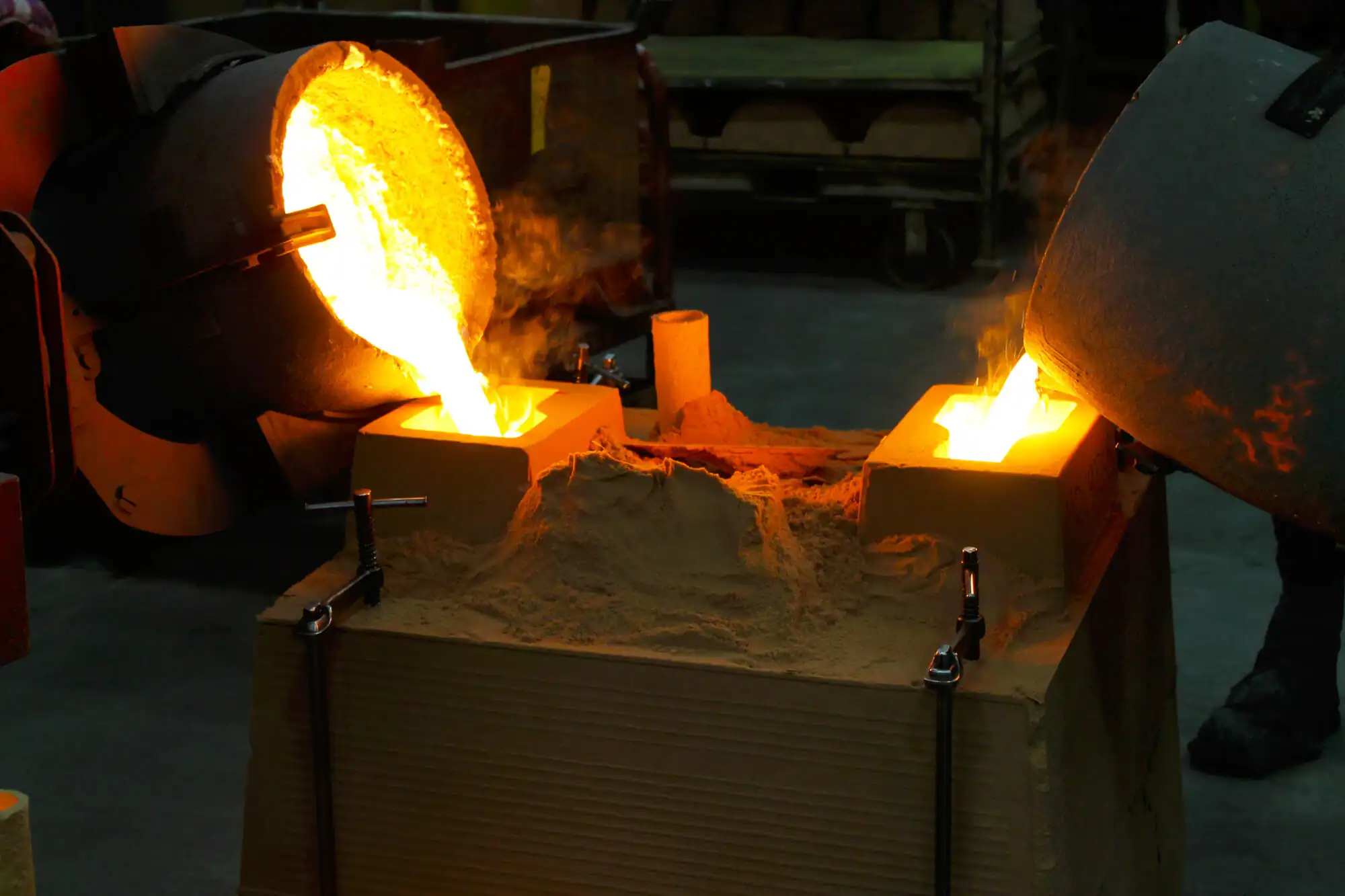

Usually overlooked, steel foundries play a crucial duty in the manufacturing procedure by changing raw steels into usable parts. These centers focus on melting various steels, such as iron, aluminum, and bronze, and pouring them right into mold and mildews to produce parts for varied markets. The process begins with the mindful selection of raw materials, ensuring that just the finest quality steels are utilized. As soon as thawed, the steel handles the shape of the mold, strengthening into elements that fulfill specific style and performance standards.Steel shops contribute significantly to fields like automobile, aerospace, and construction by supplying crucial components such as engine blocks, equipments, and architectural assistances. Their expertise in alloy formulation and spreading methods enables producers to generate complex styles while preserving stamina and toughness. Consequently, steel foundries not only promote the production of vital components however also enhance the overall efficiency and functionality of modern production.

Enhancing Manufacturing Performance Via Advanced Techniques

Steel foundries are increasingly taking on advanced techniques to enhance production effectiveness and satisfy the growing needs of various markets. The application of automation and robotics has structured procedures, minimizing hands-on labor and enhancing precision in metal spreading operations. In addition, the integration of computer-aided layout (CAD) and simulation software permits for far better planning and optimization of manufacturing operations, decreasing waste and minimizing lead times.Lean producing concepts are also being used to remove inefficiencies and enhance resource utilization. Foundries are currently concentrating on energy-efficient methods, such as making use of waste warm recuperation systems, which better add to cost savings and ecological sustainability. By accepting these sophisticated techniques, steel factories are not only boosting their functional efficiency yet likewise enhancing item top quality, causing higher consumer complete satisfaction. As industries continue to advance, the ability of shops to adapt to these developments will certainly be important for keeping competition out there.

Technologies in Steel Casting Innovation

As the demand for precision and efficiency in making grows, technologies in steel casting modern technology are transforming the sector landscape. Improvements such as 3D printing and computer-aided style (CAD) are allowing factories to generate complicated geometries with better accuracy and rate. These methods minimize material waste and reduce preparations, promoting a more lasting production procedure.

Smart foundry innovations, consisting of the Net of Points (IoT), help with real-time surveillance and information evaluation, enhancing production performance and reducing downtime. Jointly, these innovations are not just boosting the abilities of metal shops but additionally establishing the phase for the future of manufacturing, identified by raised agility and responsiveness to market needs.

The Economic Impact of Metal Shops on Neighborhood and Global Markets

Metal shops play a necessary role fit economic landscapes, both locally and internationally. They generate substantial task production chances and contribute to trade and export, strengthening overall economic growth. Furthermore, foundries support regional company environments, promoting synergistic partnerships that enhance neighborhood resilience.Task Development Opportunities

Task development in the steel shop industry considerably influences both worldwide and local economies. These centers give countless job opportunity across numerous skill levels, from skilled labor to design and administration positions. The need for metal elements in industries such as automobile, aerospace, and building drives the requirement for a robust workforce. As steel factories expand, they boost extra task creation in supplementary markets, including transportation, logistics, and supply chain management. In addition, the economic stability provided by foundry jobs adds to local communities through raised costs and investment in facilities. Overall, the metal shop market's capability to develop work not only boosts specific source of incomes yet likewise bolsters local growth and strength, showcasing its critical duty in economic development.

Export and Trade Contributions

A substantial portion of the financial effect created by factories comes from their contributions to trade and export. Metal foundries play a crucial function in supplying elements for numerous sectors, including vehicle, aerospace, and building, thereby improving a nation's export capacities. By generating top quality castings and elements, factories allow neighborhood economic climates to contend on a global range. The export of these products not only raises revenue yet also promotes worldwide partnerships and trade contracts. Furthermore, foundries add to a positive trade equilibrium, which is vital for economic stability. The export tasks of steel shops boost technology and investment, eventually strengthening their significance in both international and regional markets, driving growth see here and economic strength.Resident Company Support Equipments

While local economic climates typically gain from the visibility of steel shops, their effect expands beyond mere task production. These facilities contribute substantially to neighborhood business assistance systems by fostering a network of distributors, provider, and secondary sectors. This interconnected environment improves financial resilience, enabling smaller services to thrive along with bigger shops. Additionally, metal shops typically participate in area campaigns, buying local framework and education, which better boosts economic development. On a broader scale, the existence of shops can attract financial investment and skill, strengthening the region's affordable benefit in global markets. Eventually, the economic payments of metal foundries not only produce straight employment yet also grow an encouraging environment for varied neighborhood enterprises.Obstacles Facing Steel Shops in the Modern Age

As the steel factory sector develops, it encounters many difficulties that endanger its sustainability and competition. One considerable problem is the boosting expense of raw products, which straight influences manufacturing expenditures. Worldwide supply chain disturbances even more worsen this problem, making it hard for foundries to maintain consistent procedures. In addition, labor scarcities offer a considerable obstacle, as proficient employees come to be limited in a quickly transforming technological landscape.Furthermore, steel shops must emulate stringent ecological guidelines that demand higher conformity prices and financial investment in cleaner innovations. This shift calls for shops to adapt rapidly, frequently straining economic resources.

Finally, competitors from automated production procedures and overseas manufacturing includes pressure, forcing neighborhood shops to risk or introduce obsolescence. Attending to these difficulties is vital for the sector to prosper in a increasingly complex and affordable market setting.

Sustainability Practices in Steel Founding

In feedback to the obstacles faced by the industry, steel factories are my company progressively adopting sustainability methods to enhance their operational effectiveness and ecological responsibility. These techniques consist of the implementation of energy-efficient innovations, such as electrical induction furnaces, which decrease energy consumption and greenhouse gas exhausts. In addition, numerous foundries are focusing on recycling scrap metal, minimizing waste, and using environmentally friendly materials to decrease their environmental impact.

Water preservation procedures are likewise being focused on, with systems developed to recycle process water, consequently decreasing freshwater use. Foundries are investing in staff member training programs to advertise sustainable methods amongst workers, promoting a culture of environmental understanding.

Future Trends in the Steel Shop Industry

Shifting and emerging modern technologies market needs are positioned to reshape the steel shop market in the coming years. Boosting automation, driven by improvements in robotics and expert system, is expected to boost production efficiency and minimize labor costs. Metal Casting. Furthermore, additive production techniques, such as 3D printing, are gaining traction, permitting for even more complicated and tailored metal parts with minimized wasteSustainability will additionally play an essential duty, with factories embracing greener practices to decrease their ecological influence. The industry is most likely to see a rise in the usage of recycled products as raw inputs, aligning with international sustainability objectives.

In addition, the demand for light-weight and high-performance alloys, particularly in the aerospace and automotive markets, is expected to increase. This advancement will certainly demand continuous investment in study and growth, allowing steel shops to adjust and grow in a competitive landscape. In general, these fads are established to redefine the operational landscape of steel factories.

Regularly Asked Concerns

What Types of Metals Are Typically Used in Shops?

Usual metals made use of in foundries consist of iron, zinc, aluminum, and copper. These materials are favored for their unique buildings, enabling diverse applications in sectors such as vehicle, aerospace, and building, contributing substantially to manufacturing processes.Just How Do Steel Foundries Make Certain Product Quality and Uniformity?

Metal shops guarantee product high quality and consistency through rigorous quality assurance procedures, consisting of precise temperature guideline, material screening, and adherence to industry criteria. Normal assessments and knowledgeable workmanship even more improve integrity and uniformity in manufacturing procedures.What Precaution Are Applied in Steel Shops?

Metal foundries carry out safety and security procedures such as personal safety tools, air flow systems, routine safety and security training, and rigorous adherence to safety protocols to lessen dangers. These techniques intend to shield employees and preserve a secure working environment.What Are the Job Opportunities in the Steel Foundry Sector?

Career opportunities in the metal factory industry include duties such as factory workers, quality assurance inspectors, engineers, maker operators, and monitoring settings. These roles demand different abilities, offering pathways for development and expertise within the area.Just How Do Foundries Deal With Waste and Recycling of Materials?

Factories handle waste and recycling with processes like recovering sand, melting scrap metal, and making use of by-products for power. These techniques minimize environmental impact while promoting sustainability within the steel casting sector and enhancing source effectiveness.Frequently forgotten, metal factories play a crucial role in the production process by transforming raw steels into useful elements. Steel factories are progressively taking on innovative strategies to enhance manufacturing try this efficiency and satisfy the growing needs of numerous markets. Metal factories play a necessary duty in providing components for different sectors, consisting of automotive, aerospace, and construction, consequently boosting a nation's export capabilities. In feedback to the challenges faced by the sector, metal factories are increasingly embracing sustainability practices to enhance their operational performance and ecological responsibility. Metal Casting. Profession possibilities in the metal shop industry include duties such as foundry workers, top quality control assessors, designers, machine drivers, and management settings

Report this wiki page